A Comprehensive Overview to the Sorts Of Ceramic Coating on the marketplace

Ceramic finishings have emerged as a pivotal remedy across different industries due to their special residential or commercial properties and applications. As we explore the unique qualities and applications of these layers, the ramifications for efficiency and longevity end up being progressively evident, increasing questions regarding which type might ideal match your requirements.

Recognizing Ceramic Coatings

Ceramic layers are advanced protective remedies that have actually gained popularity in various industries, specifically in vehicle and aerospace applications. These finishings contain a fluid polymer that, when treated, creates a durable, hydrophobic layer externally of the substratum. This layer offers boosted resistance to ecological impurities, UV radiation, and chemical exposure, consequently extending the life and visual appeal of the underlying product.

The basic component of ceramic layers is silica, which adds to their solidity and resilience. The application process commonly includes surface preparation, application of the coating, and treating, which can be accomplished through warm or UV light. As soon as treated, ceramic layers exhibit exceptional bonding properties, allowing them to stick strongly to a variety of surface areas, including steels, plastics, and glass.

In enhancement to their safety features, ceramic finishings additionally provide ease of maintenance. Their hydrophobic nature decreases the adherence of dust and grime, making cleaning easier and much less constant. Overall, the fostering of ceramic finishings represents a significant innovation in surface area defense technology, providing both functional and visual advantages across several industries.

Sorts Of Ceramic Coatings

Numerous kinds of ceramic finishings are offered, each created to meet particular performance demands and applications - scratch repair sarasota. The most typical kinds consist of:

Silica-based Coatings: These coverings largely are composed of silicon dioxide and are understood for their resilience and chemical resistance. They are extensively utilized in vehicle and industrial applications.

Titanium Dioxide Coatings: Popular for their photocatalytic residential or commercial properties, titanium dioxide layers are usually used in atmospheres where self-cleaning and antifungal residential or commercial properties are desirable, such as in structure materials and automotive surfaces.

Zirconia Coatings: Characterized by their high-temperature security and thermal resistance, zirconia coatings are used in applications such as generator engines and high-performance auto components.

Alumina Coatings: Displaying excellent firmness and thermal stability, alumina coatings are frequently made use of in wear-resistant applications, including reducing devices and commercial machinery. - scratch repair sarasota

Crossbreed Coatings: Integrating the buildings of numerous products, hybrid finishes supply boosted efficiency qualities, making them appropriate for unique and requiring applications.

Each kind of ceramic coating offers unique functions, allowing customers to choose one of the most appropriate service based upon details ecological problems and performance requirements.

Advantages of Ceramic Coatings

Ceramic layers, in particular, offer many benefits that make them significantly prominent amongst makers and customers alike. These coatings are immune to scrapes, chemicals, and UV rays, guaranteeing that the underlying surface remains safeguarded over time.

In enhancement to toughness, ceramic layers offer excellent hydrophobic properties, enabling for simple cleansing and maintenance. This water-repellent nature minimizes the adherence of dirt, gunk, and other contaminants, which can prolong the visual appeal and performance of the surface. In addition, ceramic coverings can dramatically enhance thermal resistance, making them suitable for applications that endure high temperatures.

Application Process

When applying ceramic coatings, a meticulous approach is necessary to accomplish ideal outcomes. A clean surface area ensures appropriate adhesion of the finishing.

Once the surface area is prepped, the following step is to apply the ceramic coating. The covering ought to be applied in thin layers, as thicker applications can lead to irregular coatings.

After application, the finishing calls for a particular healing time, commonly ranging from a few hours to a complete day, relying on the product. During this time, it is important to avoid exposure to wetness or impurities. Ultimately, a mild buffing may be necessary after curing to click for source boost the gloss and eliminate any high spots. Following these steps diligently will maximize the performance and longevity of the ceramic coating, supplying a sturdy safety layer for the surface.

Maintenance and Longevity

To make sure the long life and performance of a ceramic coating, normal upkeep is important. Ceramic layers, understood for their durability and protective high qualities, need specific care regimens to optimize their life-span and efficiency. The initial step in maintenance entails regular cleaning with pH-neutral soap, preventing severe chemicals that can weaken the coating. It is a good idea to clean the vehicle regularly, preferably every two weeks, to stop the accumulation of contaminants that can compromise the layer's honesty.

In enhancement to normal cleaning, routine inspections are critical. Try to find indicators of wear or damages, such as hydrophobic residential or commercial properties lessening or surface area blemishes. If necessary, a light gloss may be used to invigorate the finishing without stripping it away.

Additionally, the application of a booster spray can boost the coating's hydrophobic effects and restore its gloss. This is particularly helpful for layers that have actually remained in use for a prolonged duration. Inevitably, by adhering to these maintenance methods, one can significantly best site expand the life of a ceramic finish, making certain that it proceeds to provide ideal security versus ecological variables and maintain explanation the visual appeal of the automobile.

Conclusion

Joseph Mazzello Then & Now!

Joseph Mazzello Then & Now! Danny Pintauro Then & Now!

Danny Pintauro Then & Now! Suri Cruise Then & Now!

Suri Cruise Then & Now! Mary Beth McDonough Then & Now!

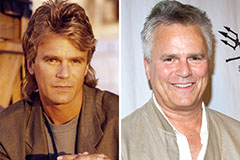

Mary Beth McDonough Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!